How the commonly used plastic bottles or glass bottles are made?

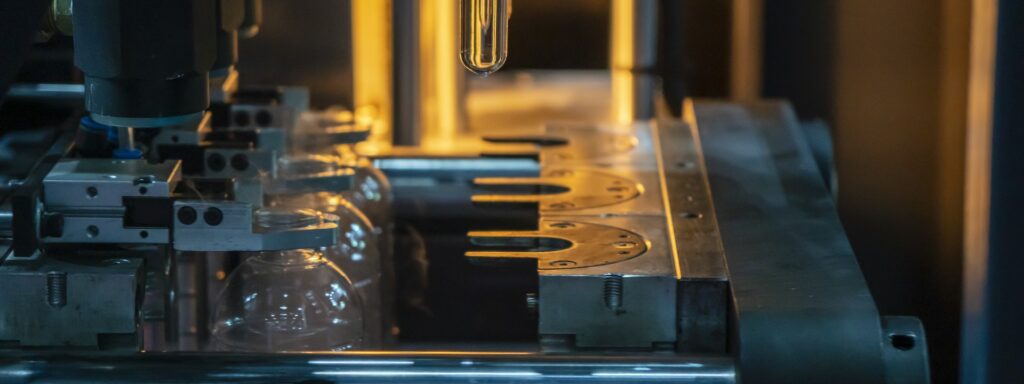

Do you know how the plastic bottles or glass bottles are produced? Yes,model blowing. It also known as hollow model blowing, is a rapidly developing plastic processing method.This is a processing method used in plastic manufacturing process that uses gas pressure to inflate a hot-melt parison closed in a mould to form a hollow product.The blow molding began to be used to produce low-density polyethylene vials during World War II. In the late 1950s, with the birth of high-density polyethylene and the development of blow molding machines, blow molding technology has been widely used.

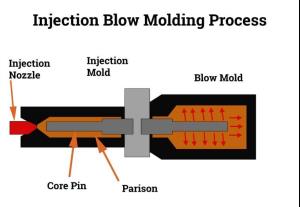

The volume of hollow containers can reach thousands of liters, and some production has adopted computer control. Plastics suitable for blow moulding include polyethylene, polyvinyl chloride, polypropylene, polyester, etc. The resulting hollow containers are widely used as industrial packaging containers. Blow molding is further divided into extrusion blow molding and injection blow molding, in which extrusion blow molding cost less, while injection blow molding provides more controllable parameters, such as wall thickness and weight.

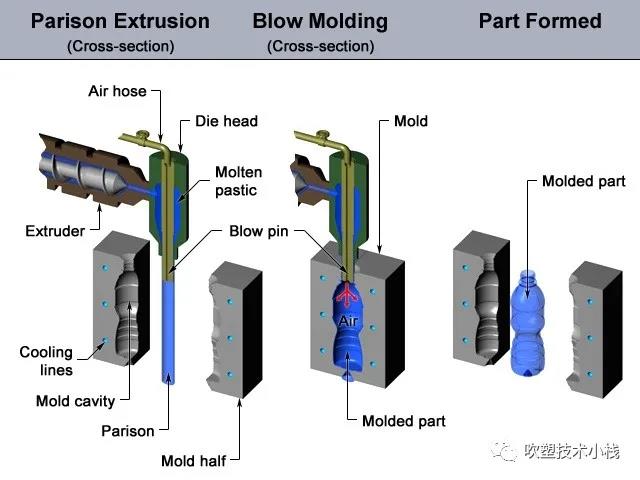

The blow molding process consists of several standard steps:

- The parison is installed on the nozzle of the machine, and then put into the mould, which is divided into two halves.

- The hot air passes through the blowing head to form a billet, expanding to the shape of the mould.

- Cool in the mould for a few seconds before demoulding.

- Remove extra material at both ends to finalize the product.

For economic considerations, it is necessary to produce thousands of pieces per hour. Blow molding manufacturing is generally mass production. With the improvement of the automation level, the cost of equipment decreases, and one worker can control the operation of multiple automation equipment, and the labor cost is low.

Extrusion blow molding

Injection blow molding

You can click the link below to have a look at the bottle making.

https://youtu.be/A_M8WBJMcM0?si=nHSCs2tAndm6w3zg