Reasons Why PET Plastic is a Reliable Option for Packaging Food and Beverages

With benefits that range from safety to environmental sustainability, PET plastic is an ideal choice for ensuring the secure and efficient packaging of food and drinks. Let’s explore the reasons behind PET plastic’s popularity in this industry.

What is the raised area found on the rim of an aluminum can?

When consumers pop open a beverage can, their attention typically centers on the ease of the pull tab. However, many overlook the subtle raised metal feature that encircles the can's opening. While it may appear trivial, this design element is a remarkable achievement in contemporary industrial engineering. It serves as both a "safety lock" to seal the beverage and a testament to advancements in materials science, mechanical engineering, and precision fabrication.

Creative Package shines at the 2025 Canton Fair and expands its global presence

In 2025, the 130th China Import and Export Fair (Canton Fair) was held in Guangzhou, a commercial feast that brought together global buyers and suppliers. Anhui Chuangbao Technology Group Co., Ltd. made a grand appearance with its rich and diverse packaging products. With its outstanding strength and innovative achievements in the packaging field, it attracted many professional visitors and potential customers from all over the world.

Square Glass Jars with Lids Vs. Round Glass Jars for Food Storage

When considering sustainability, glass jars—both round and square with lids—serve as eco-conscious options compared to plastic containers. Nonetheless, square glass jars hold an advantage in shipping logistics. Their shape allows for more efficient packing, which minimizes the need for additional packaging materials and ultimately lowers your carbon footprint.

Frequent issues and their remedies encountered in the manufacturing of easy-open lids.

It is widely recognized that two-piece aluminum cans offer numerous benefits, including their lightweight nature and ease of transport; they are also resistant to breakage, ensuring safety. Their outstanding sealing capabilities and extended shelf life for contents have established these cans as the preferred choice for beverage packaging among consumers in both the United States and Europe, leading to consistently high demand. Additionally, there is a significant market potential for aluminum easy-open ends.

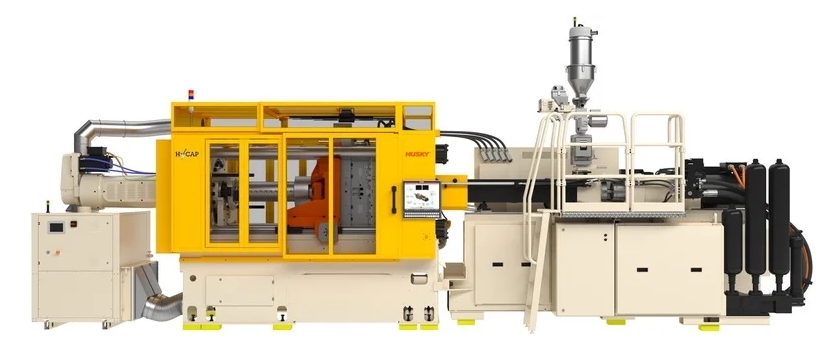

Plastic Products Production: Selecting Between Injection and Compression Molding

Compression molding is a manufacturing technique that utilizes pressure to shape preheated materials into specific forms. In contrast to injection molding, which uses a multi-cavity mold to create multiple parts in one cycle, compression molding features a machine with a carousel containing several single-cavity molds, each producing one closure at a time.

The Trump Administration is imposing a 25% tariff on imported canned beer and empty cans from around the world.

As aluminum prices continue to rise, domestic suppliers may experience a rise in their overall input costs, though likely not as significantly. The alcohol industry, particularly spirits and wine, will also face tariff impacts, but the extent of these effects is still uncertain. As the U.S. prepares for potential retaliatory measures, the length of time tariffs will remain in place will undoubtedly be a topic for further debate.

What is the injection molding process?

In the dynamic, ever-changing world of beverage packaging design, choosing the right manufacturing method is essential to creating high-quality plastic products. Injection molding is one of the common technologies used to produce plastic products, and in this article, we will take a closer look at this method, enabling you to make an informed decision to meet your specific requirements.

How Can You Craft a Product That Shines on Social Media?

To successfully launch a branded product that resonates on social media, it takes more than just having a quality item. It requires a thoughtful blend of eye-catching design, collaboration with influencers, tailored engagement for specific platforms, and creative packaging solutions. Given that billions of users are active on different social networks, these platforms are vital marketing avenues for brands aiming to enhance their visibility, cultivate customer loyalty, and boost sales.